Sk200 Digger Loader Case Backhoe Bucket Bolt Forging Teeth for Kobelco

SK200 digger loader case backhoe bucket bolt forging teeth for Kobelco Applicable models: Komatsu, Hitachi, Daewoo, Cate;

Basic Info.

| Model NO. | SK200 |

| Application | Excavator |

| Certification | CE, ISO9001: 2000 |

| Condition | New |

| Color | as Demand |

| Weight | 9.2kgs |

| Bucket Type | Standard Bucket |

| Suitable Excavator | 1.2ton, 20ton, 70ton, 1ton, 4ton, 9ton, 50ton, 35t |

| Delivery | 15-30 Days Per Container |

| Exported Countries | Egypt, Turkey, Vietnam, Philippines, Indonesia etc |

| Origin of Country | China |

| Applicable Industry | Construction, Earthmoving, Engineering, Coal, Work |

| Surface Hardness | 47-52 HRC |

| Applications | Excavator, Loader, Bulldozer, etc. |

| Finish | Smooth |

| Suitable Machine | Caterpillar; Komatsu; Jcb; Hyundai; XCMG; Sany.... |

| Material | Alloy Steel |

| Product Name | Excavator Bucket Teeth |

| Technique | Forging/ Forged |

| Transport Package | Plywood Case |

| Specification | bucket teeth |

| Trademark | FOCUS |

| Origin | China |

| HS Code | 84314999 |

| Production Capacity | 500000 PCS Per Mont |

Product Description

SK200 digger loader case backhoe bucket bolt forging teeth for Kobelco

Applicable models: Komatsu, Hitachi, Daewoo, Caterpillar, Volvo, Hyundai, XCMG, Sany, Zoomlion, Kobelco, Sangong, Lonking, etc.

| Bucket Teeth | |||

| Material | Alloy steel | Part No. | 205-70-19570/PC200RC |

| Color | Metal color or Customer's Request | N.W. | 5 kgs |

| Logo | Our logo or Customer's Request | Packing | Plywood case |

| Hardness | HRC 47-52 | Suitable machine | Caterpillar; Komatsu; JCB; Hyundai; Doosan... |

| MOQ | 1 pc | Certificates | ISO9001: 2015; SGS |

| Delivery time | 30-35 days (one container) | Loading Port | Qingdao; Shanghai; |

| Warranty | 12 months | Payment | T/T; L/C; Western Union... |

| Other hot selling models | |||||

| Suitable Machine No. | Part No. | Weight | Suitable Machine No. | Part no. | Weight |

| (KG) | (KG) | ||||

| PC200 | 205-70-19570 | 3.7 | J200 | 1U3202 | 1.4 |

| 205-70-19570RC | 4.5 | 1U3201 | 1.2 | ||

| 205-939-7120 | 8.4 | 1U3202RC | 1.5 | ||

| 35S/205-70-74272 | 4.5 | J300 | 1U3302 | 3.8 | |

| PC300 | 207-70-14151 | 6.2 | 1U3302RC | 5.8 | |

| 207-70-14151RC | 7.5 | 6Y6335/9W1879 | 3.1 | ||

| 939-5120 | 10.2 | J450 | 9W8552 | 12 | |

| 40S/207-70-34212 | 7.1 | 1U3452RC | 12.6 | ||

| PC400 | 208-70-14152 | 9.6 | J550 | 9W8552 | 20.4 |

| 208-70-14152RC | 12.3 | 9W8552RC | 19 | ||

| 208-939-3120 | 20.5 | 6I6554 | 31.8 | ||

| And so on | |||||

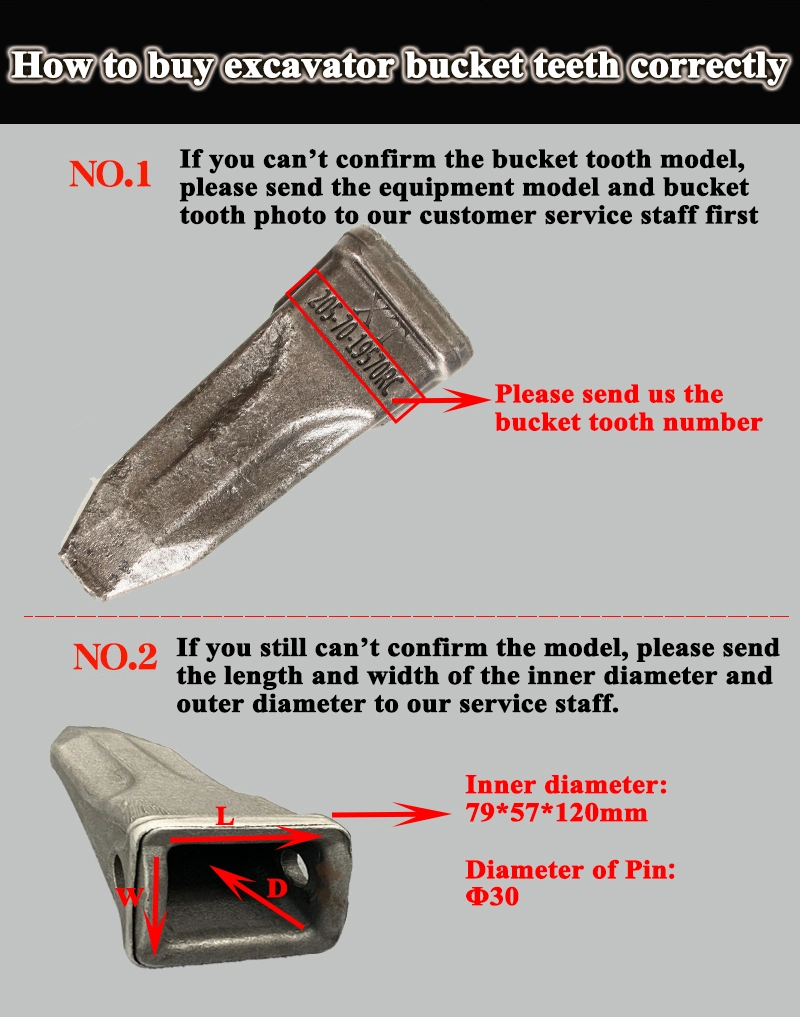

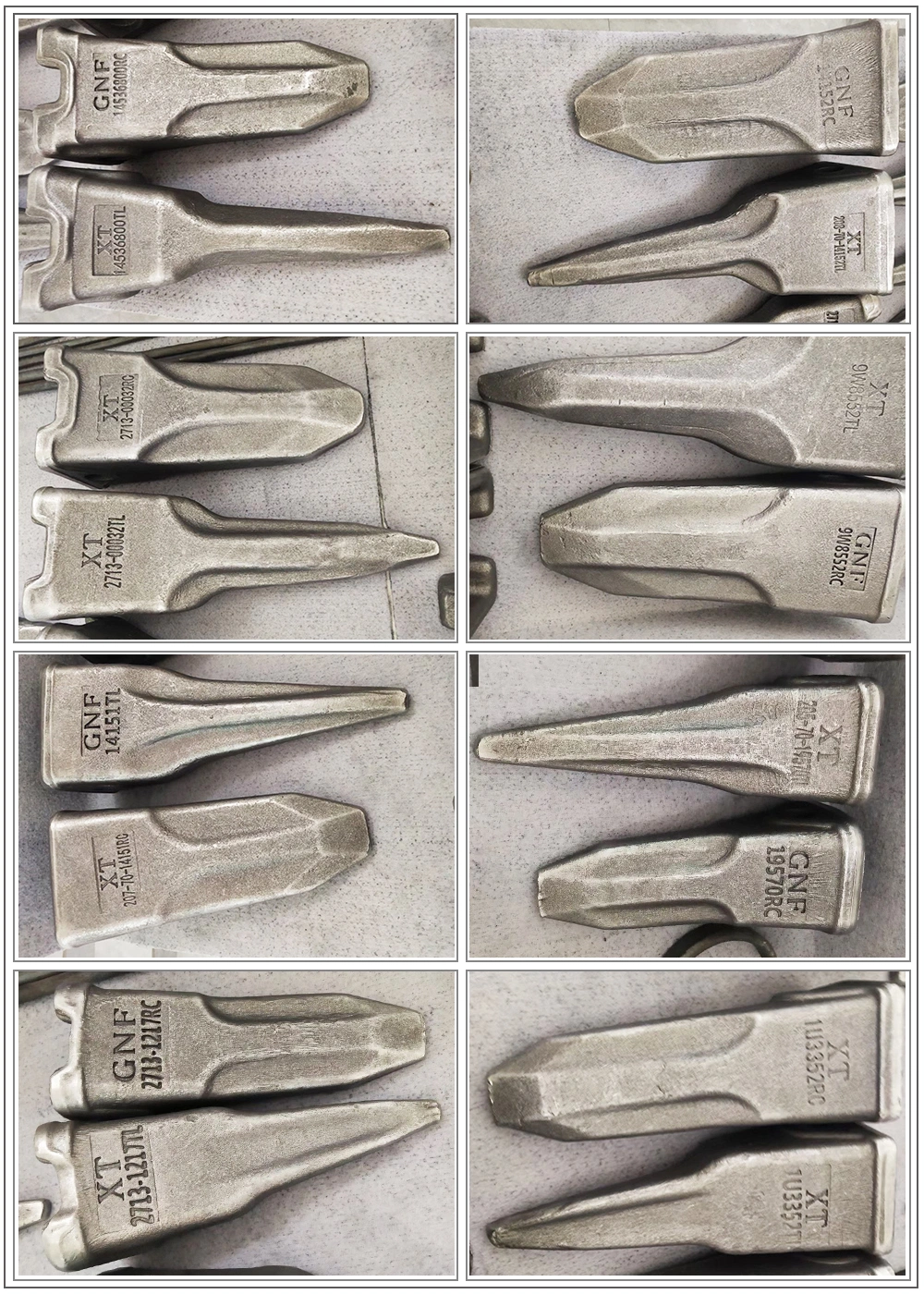

Models display

Tips for using bucket teeth

1. Practice has proved that during the use of excavator bucket teeth, the outermost tooth of the bucket wears about 30% faster than the innermost tooth. It is recommended to change the position of the bucket teeth exceptionally after a period of time.--------------------------------------------------------------------------------------------------------------------------------------------------2. In the process of using bucket teeth, please choose bucket teeth according to different work types. For general excavation, weathered sand, surface media, etc., flat-head bucket teeth are used. RC type bucket teeth are used for digging massive hard rocks, and L type bucket teeth are generally used for digging massive coal seams. TL bucket teeth can increase the rate of coal lump generation. In actual use, users often like general-purpose RC type bucket teeth. It is recommended not to use RC type bucket teeth under special circumstances. It is best to use flat-head bucket teeth, because RC type bucket teeth will look like "fists" after being worn out for a period of time. The digging resistance is large, and power is wasted. The bottle-mouth bucket teeth always maintain a sharp surface during the abrasion process, which reduces the digging resistance and saves fuel.--------------------------------------------------------------------------------------------------------------------------------------------------3. The driving method of the excavator driver is also very important to improve the utilization of the bucket teeth. The driver should try not to retract the bucket when lifting the boom. If you raise the boom while retracting the bucket, this operation will cause the bucket teeth When receiving an upward traction force, the bucket teeth are torn apart from the top, and the bucket teeth are torn apart. Pay special attention to the coordination of the action during this operation. Some drivers often use too much force in the action of expanding the arm and sending the forearm, and quickly "knock" the bucket against the rock or force the bucket against the rock. This will break the bucket teeth or easily Knock the digging bucket to the cracks, knock the big and small arms.--------------------------------------------------------------------------------------------------------------------------------------------------4. The wear of the tooth seat is also very important to the service life of the bucket teeth of the excavator. It is recommended to replace the tooth seat after the tooth seat is worn out by 10% to 15%, because there is an excessively worn tooth seat and the bucket teeth. The large gap changes the fit and stress point of the bucket tooth and the tooth seat, and the bucket tooth will break due to the change of the force point.--------------------------------------------------------------------------------------------------------------------------------------------------5. The excavator driver should pay attention to the digging angle during operation, try to master it when digging, and the bucket teeth are perpendicular to the working surface when digging down, or the camber angle is not more than 120 degrees to avoid breaking the bucket teeth due to excessive inclination. . Also need to be careful not to dig the excavating arm left and right under the condition of large resistance, this will cause the bucket teeth and the tooth seat to be broken due to excessive force on the left and right, because the mechanical design principle of most models of bucket teeth does not consider the force on the left and right. design.1**You please send us your enquiry; 2**We shall reply you with the quotation within 12 hours; 3**We negotiate on the configuration that you need; 4**Confirmation of the tech data → sign contract (P/I) → 30% deposit (or L/C issuing)→ production; 5**Manufacturing process updated news → completing production; 6**Balance payment → ex works → shipment → custom clearance → A/S service for 1 year. Service Promise1.24-hours hot line at your service, available for quality and extending service. 2. Lifelong free technical guidance service can be provided. 3. For Customers who buy bulk quantity for the first time, we can send service technicians to offer site instruction serviceAnd short- term stationary point service. 4. Free technical training can be provided to help customers use and maintain the trucks and trailers quickly and correctly. Why Choose Focus vehicles?--WHAT ARE OUR ADVANTAGES ?**Competitive price--We work as the leading dealers of Various leading China TRUCKS and SEMI TRAILERS, and Construction machinery manufactures/factories, and are treated with best dealership prices every year. From comparison and feedbacks from clients, Our price is more competitive than others even manufacturers/ factories.**Ouick Response--Our team is consisted of a group of dilligent and enterprising people.Working 24/7 to respond client inquires and question all the time. Most problems can be solved within 12 hours.**Fast Delivery--Normally it will take more than 30 days for manufacturers/factories to produce the ordered machine, while we have a variety of resources, locally and nation widely, to receive machines timely manner.--WHICH PAYMENT TERMS CAN WE ACCEPT?Normally we can work on T/T term or L/C term.**On T/T term, 30% downpayment is required in advance, and 70% balance shall be settled before shipment, or against the copy of origial B/L for old clients.**On L/C term, a 100% Irrevocable L/C without "soft clauses" can be accepted. Please seek the advice from the individual sales manager whom you work with.--HOW LONG WILL OUR PRICE BE VALID?We are a tender and friendly supplier, never greedy on windfall profit. Basically, our price remains stable through the year, We only adjust our price based on two situations:** The rate of USD: RMB varies significantly according to the international currency exchange rates.** Manufacturers/Factories adjusted the trucks and machinery price, becaue of the increasing labor cost, and raw material cost.--WHAT LOGISTICS WAYS WE CAN WORK FOR SHIPMENT?We can ship trucks, trailers and machinery by various transportation tools.**For 90% of our shipment would go by sea, to all main continents such as South America, Middle East, Africa, Oceania and Europe etc. either by container or RoRo /Bulk shipment.**For neighborhood countries of China, such as Russia, Mongolia, Kazakhstan, Uzbekistan etc., We can ship trucks trailers, machinery by Road or Railway.**For light spare parts in urgent demand, we can ship it by international courier service. such as DHL, UPS, TNT, or Fedex.

Contact:Sindy ChenMobile:+ 86 15890188201

You may also like

Send inquiry

Send now